Jwell PP One Mould Double Out Plastic Building Template Extruder Machine/Plastic Machine

Description:

This production line is made by Jwell on the basis of the traditional 915mm single out production line,that not only could meet the demand of large output and low energy,but also could achieve the best product quality stability.

Features:

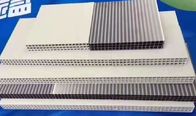

1. PP hollow plastic building template board has high strength, impact resistance, wear resistance, long service life, and turnover frequency can reach more than 100 times.

2. PP hollow plastic construction template has good machinability, can be sawed, planed, nailed, and can be used together with wood formwork.

3. PP hollow plastic building templates on both surfaces (smooth or decorative) have different effects. If the smooth surface is used to complete the demolishing of the concrete after the concrete is poured, the surface of the carcass is smooth and smooth, and the requirements for the finish and decorative water are achieved. No secondary plastering is required, saving materials and time, reducing the cleaning and maintenance costs, and the quality of the concrete after molding. Stability saves time. Especially suitable for basement projects, bridges and piers of highways and railways and other wet environments; if the use of patterns is conducive to the combination with the plaster layer. In particular, bridge piers use the pattern surface to meet the requirements of decorative and clean water, and because the pattern surface has a special light diffuse reflection effect, it avoids the glare reflection affecting the driver's line of sight and plays a role in safety protection.

4. The new hollow plastic building template is light in weight, easy to support and remove the mould, has low labor intensity in transportation operation, high construction efficiency, safety and reliability, no moisture absorption, corrosion resistance, acid and alkali resistance, and the surface is smooth, smooth, and does not require brushing and demoulding agent.

5. The waste board and scraps after the use of the hollow plastic building template can be recycled, which saves cost and reduces pollution.

6. The comprehensive use cost of the new hollow plastic building template can save more than 30% than the traditional wood

After-sale service:

- The warranty of our machine is 12 months and service is available lifelong.

- The cost caused by the seller’s expert in customer’s country (including shuttle trip ticket between China and the Buyer’s, inland traffic, medical fees, lodging, dinner and so on) will be covered by the buyer.

- Our expert will answer any inquiry within 24-48 hours and it will be solved as soon as possible.

- We can send enough technicians to the Buyer’s company for installation and testing the machines.

- We supplies the complete technical documents and the relative drawings of the electric components which were written in Chinese and English.

- We can provide you some easily broken spare parts.

Brief introduction of Jwell Company.

- History: Jwell is one of the biggest plastic manufactures in the world. We have many factories in Shanghai, Changzhou, Suzhou, Zhejiang and Guangzhou. We have also set up some foreign offices in Vietnam, Turky, Bangladesh and Thailand. We also started to build a factory in India. Welcome to visit our company.

- Products: We specialize in many kinds of plastic machines like plastic pipe, profile, sheet and pelletizing lines and other recycling machines. The first screw of extruder in China was made by our company in 1978. We are professional in plastic machines because of more than 40 years rich experience. Our customers come from all over the world and we can give you a turn-key system which includes materials, formula and machines. You do not need to worry about anything.

- Spirit: To be persistent and innovative; To achieve an excellent and perfect Jwell.

Packing & Shipping:

- Wooden package for Jwell plastic extrusion machines.

- Package conforms to the requirements of customs’.

- Jwell produces more than 2000 sets of extrusion machines each year, which has been sold to all over the world, including America, Brazil, Japan, Korea, India, Germany, Turnkey, Malaysia etc.

Standards: CE & ISO

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!